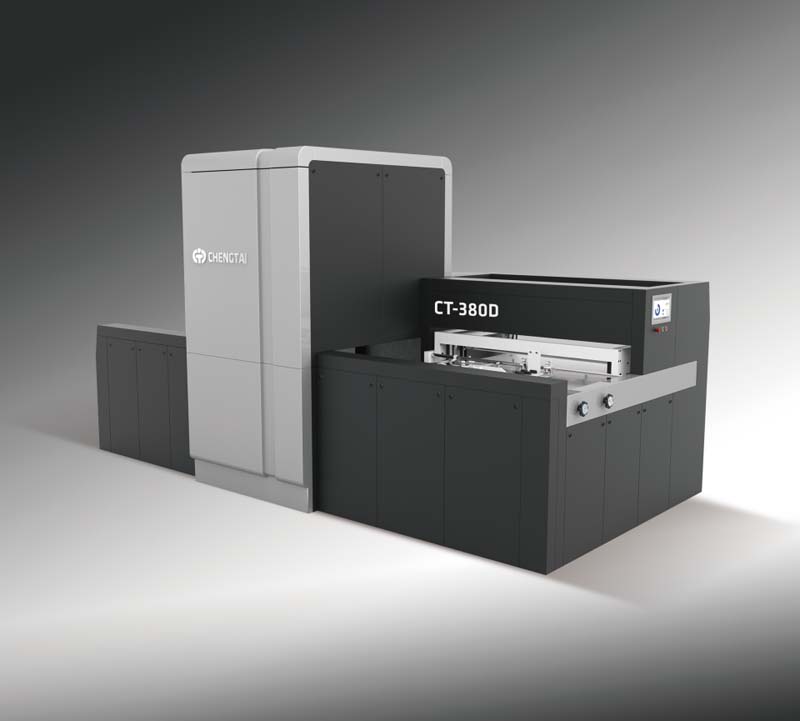

Products List

CT- 380D can bring you advantages. It makes packaging,printing, and after processing more eye-catching visual effects, feel whirling, concavity is obvious, more three- dimensional sense of the impact of a more realistic sense of depth, texture with a more beautiful, shiny clarity greatly improved, more dazzling design effects. Its cost-effective configuration to make your equipment with characteristics versatile and powerful productivity.

Advanced paper feeding mode

Using the automatic document feeder domestic original way to make paper transfer accurate, efficient, safe and stable.

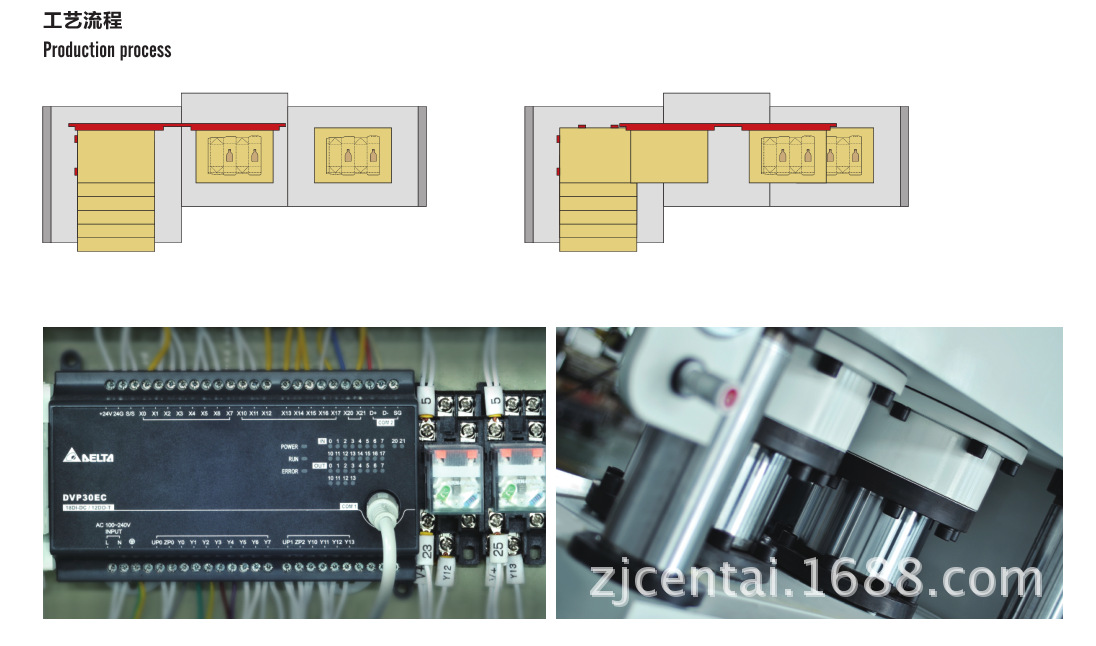

Electronic control system

Using a computer program control. Travel using non- contact proximity switches, electrical components known product.

High-quality originals

Delta PLC touch screen, servo motor, servo controllers, ball screw, pressure switch, rails, etc.

Hydraulic system

Using well- known brands, five- axis machining of high precision molding of two-way cartridge valve

Oil cooling system

Unique automatic oil temperature control system to ensure that the hydraulic system oil temperature normal, the equipment running smoothly, failure is low, and longer life.

Accessible Template

Unique interchangeable templates designed to make cleaning easier and safer for board.

Innovation stable and efficient your ideal choice

Combined effect of advanced deep embossed registration, intelligent feeding methods and new design paper transport system makes the machine easier to operate. Combined with advanced technology, higher production speed, quality is more stable, more save labor, dedicated to deep embossed ideal equipment.

Production process

Technical data

| Project | 单位(Unit) | CT-315D | CT-380D |

| Number of cylinders | 只(pcs) | 2 | 1 |

| Master cylinder pressure | 吨(T) | 315 | 380 |

| Maximum opening distance | 毫米(mm) | 80~70 | 80~70 |

| Slide stroke | 毫米(mm) | 220 | 220 |

| Maximum working pressure | 兆帕(mpa) | 25 | 25 |

| Working speed | 张/小时(Sheets/hour) | 1800~2500 | 1800~2500 |

| Table effective area | 毫米(mm) | 1050x720 | 1050x720 |

| Total power | 千瓦(kw) | 25 | 28 |

| Machine operating voltage | 伏特(V) | 380 | 380 |

| Machine size | 张/小时(Sheets/hour) | 4400x2750x2500 | 4400x2750x2500 |

| Weight | 千克(kg) | 15000 | 16800 |

Equipment and improve the quality of the performance, the machine appearance, technical parameters and characteristics are subject to change without notice.

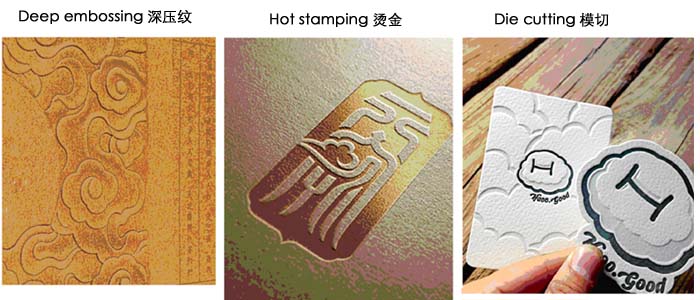

Has a number of finishing ability

Advanced hydraulic system, and greater work pressure, the unique deep embossing process optimization, Combining design screen embossing, printing will draw face more realistic. Become the pack Installed in the printing industry's top and most popular Processes.

On the installation of electrical equipment and gold foil stepping roller device, you can have hot stamping technology, good compatibility, and stability to make your products more beautiful .

Die- cutting process is a function of the device can be owned, installed on a cutting board, can be applied to thick paper production operations, puzzles, PVC plastic and die- cutting.

This machine is suitable for high- end gift packaging, such as: wine, enlarging gift box, tea box, moon cake boxes, medicine and health products boxes, calendars, greeting cards, books and gifts, etc., for applications that require deep embossed convex refractive products. The machine is safe and reliable, just one person to operate, simple saving labor.